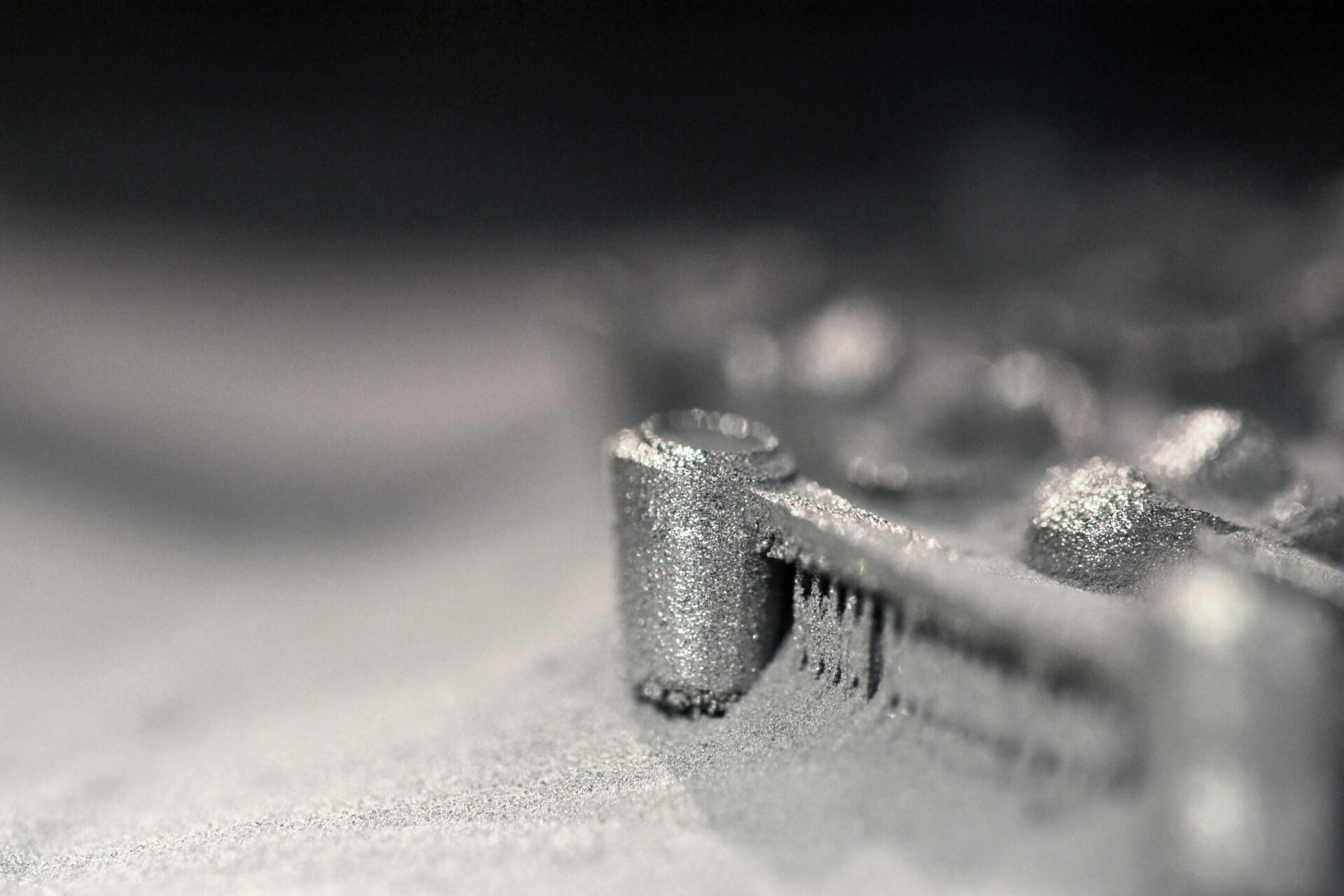

L’innovation au cœur de la performance industrielle

Adossée à un Groupe qui fut le premier il y a plus de 50 ans à créer le premier centre de recherche sur la feuille d’aluminium (1964) puis sur les pigments en 1967, Toyal Europe innove en collaboration étroite avec les équipes japonaises et place la recherche et le développement au cœur de sa performance.

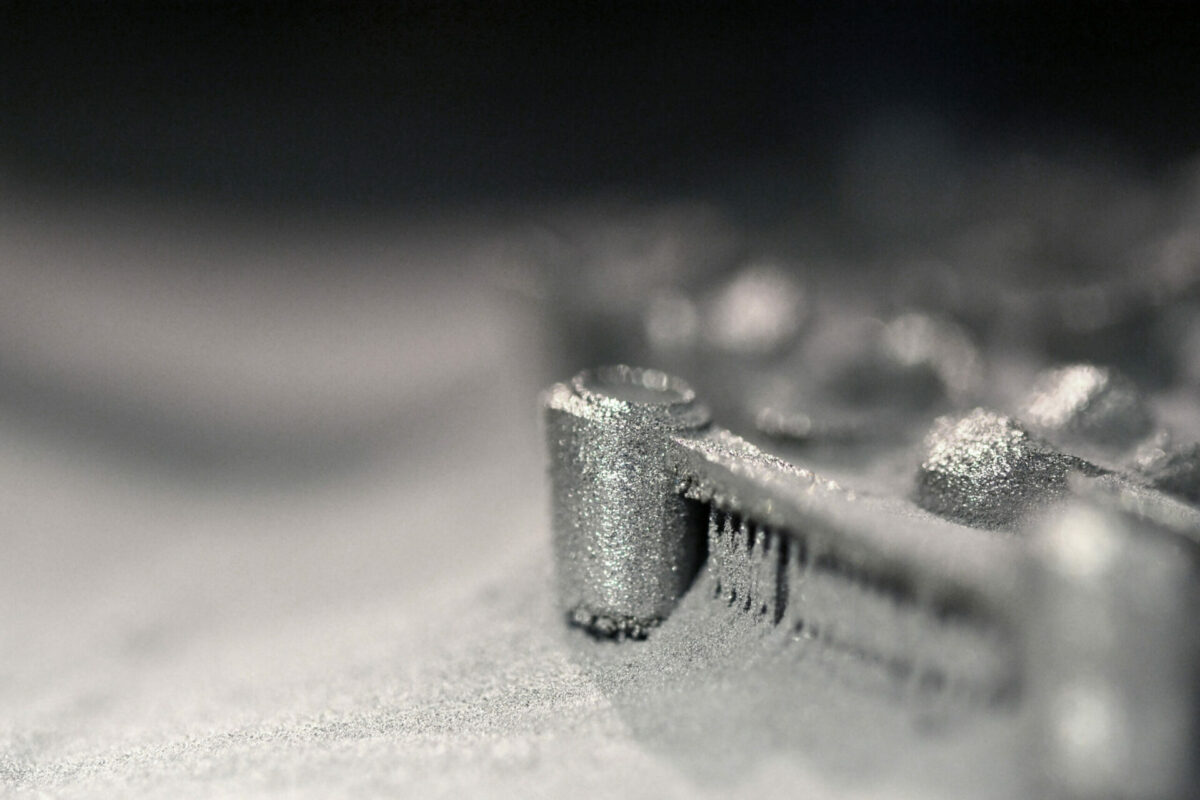

Imaginer et concevoir le futur

Innover constamment et nous efforcer à fournir des produits utilisant des technologies de pointe

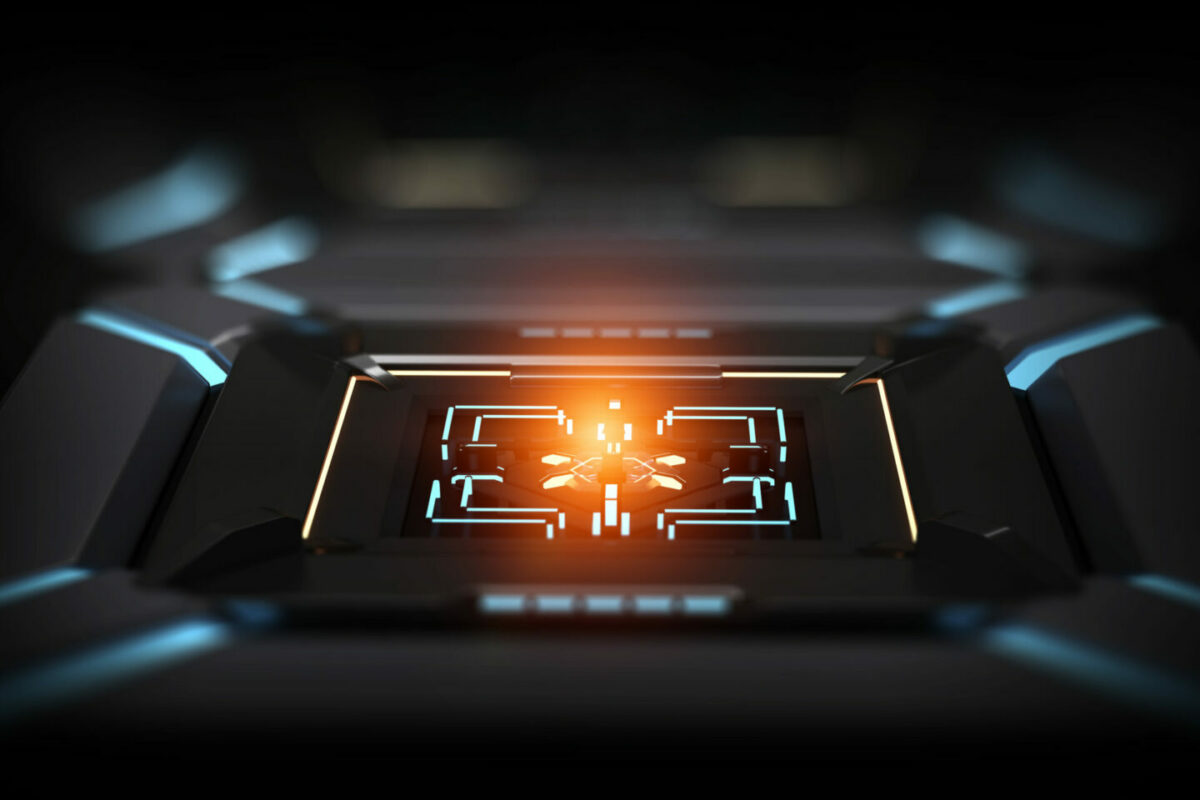

La perfection industrielle comme moteur

Promouvoir constamment l’évolution de nos process et de nos équipes

L’écoute client, au cœur de nos processus

Donner la voix aux clients et les mettre au cœur de nos organisations